Duplo PFi Blade B2+

Smart and professional solution for flatbed cutting, creasing or perforating

Using a flatbed table and digital cutting technology, the Duplo PFi Blade B2 + digital cutting table produces short-run packaging, custom cards and labels without the need for physical dies. The PFi blade cuts, kiss-cuts and creases a variety of substrates including paper, laminates, adhesives and synthetics up to 1.000mm per second and up to 6mm thick. It is an affordable and versatile solution for prototyping and short-run production.

No dies needed

Through the PFi Blade Connect software, the tri-fold tool head follows the lines designed on the cut file to finish applications in any shape. Media is held in place on the flatbed by a vacuum zone, below the conveyor belt as the tool head moves through the blade.

Simple job setup

Create the cut file in vector programs such as Adobe Illustrator and CorelDRAW to define the desired cuts, kiss cuts, and scores. Export the cut file in a number of supported formats, then upload to the PFi Connect software (PC sold separately) when the job is ready to run. Prepare the printed artwork files by adding registration marks on each corner of the sheet and a QR code. During use, the CCD registration system reads the QR code and automatically opens the corresponding cutting file in the PFi Connect software. It also reads registration marks and compensates for any image shifts to ensure each sheet is finished accurately.

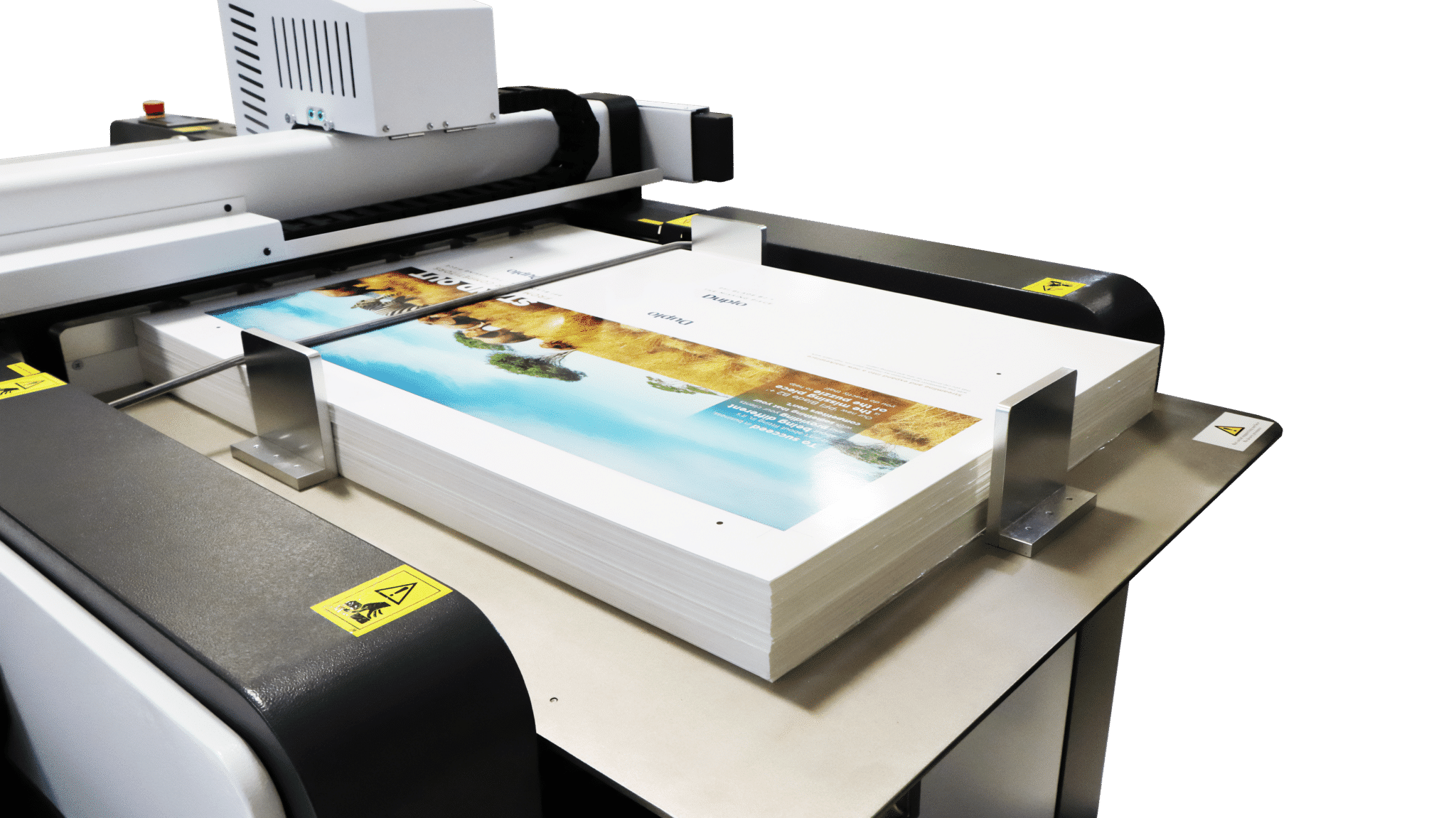

Automatic feeding system

With a stack height of 100mm, the PFi Blade remains highly productive. Each sheet is vacuum fed with the air knife assisting with sheet separation and then transported to the cutting table. The feed table raises as sheets are fed and can be reloaded without interrupting operation.

Specifications autofeeder

| feeder capacity | Up to 100mm |

| Sheet separation | Variable air settings for sheet separation |

| Feeding system | Vacuum inlet with clamps mounted on gantry |

| max. sheets size | W: 800 mm x L: 600 mm |

| min. sheets size | W: 210mm x L: 297mm |

Cut settings

| Tools | Cross section, kiss cut, creasing wheel, perforation wheel optional |

| Cutting system | Digitally controlled |

| Blade | Tungsten |

| Speed | 12-45 seconds per SRA3 sheet, depending on cut shape |

| max. cutting speed | Up to 1.200 mm/s |

| Cutting thickness | Up to 6mm |

| Tolerance | ± 0,3 mm |

Software and connectivity

| Platform | Processor I5 7500 Series Dual Core or higher, Ram 4 GB or more, Hard Drive 5 GB (SSD recommended for optimal performance), Ethernet Port: 10/100 MB x1, PCI-E 1GB Ethernet card x1, Display: 19” LCD or taller |

| File formats | Ai, EPS, jpg, Pdf, Ps and Dxf |

| Network | LAN |

| Camera registration system | CCD |

Power connections, consumption

| Voltage | 22V, 50/60Hz, 20A |

| Power | 4 kW |

| Dimensions | W: 3.200 mm x D: 1.100 mm x H: 1.100 mm |